Are you tired of high energy bills and inefficient power generation? Look no further than combined cycle turbines. These innovative machines not only produce electricity, but also capture waste heat to generate even more power. In this blog post, we’ll explore the many benefits of combined cycle turbines and why they’re quickly becoming a popular choice for energy production around the world. So sit back, relax and get ready to learn how these amazing turbines can help maximize your efficiency and save you money on your energy bill!

Introduction to Combined Cycle Turbines

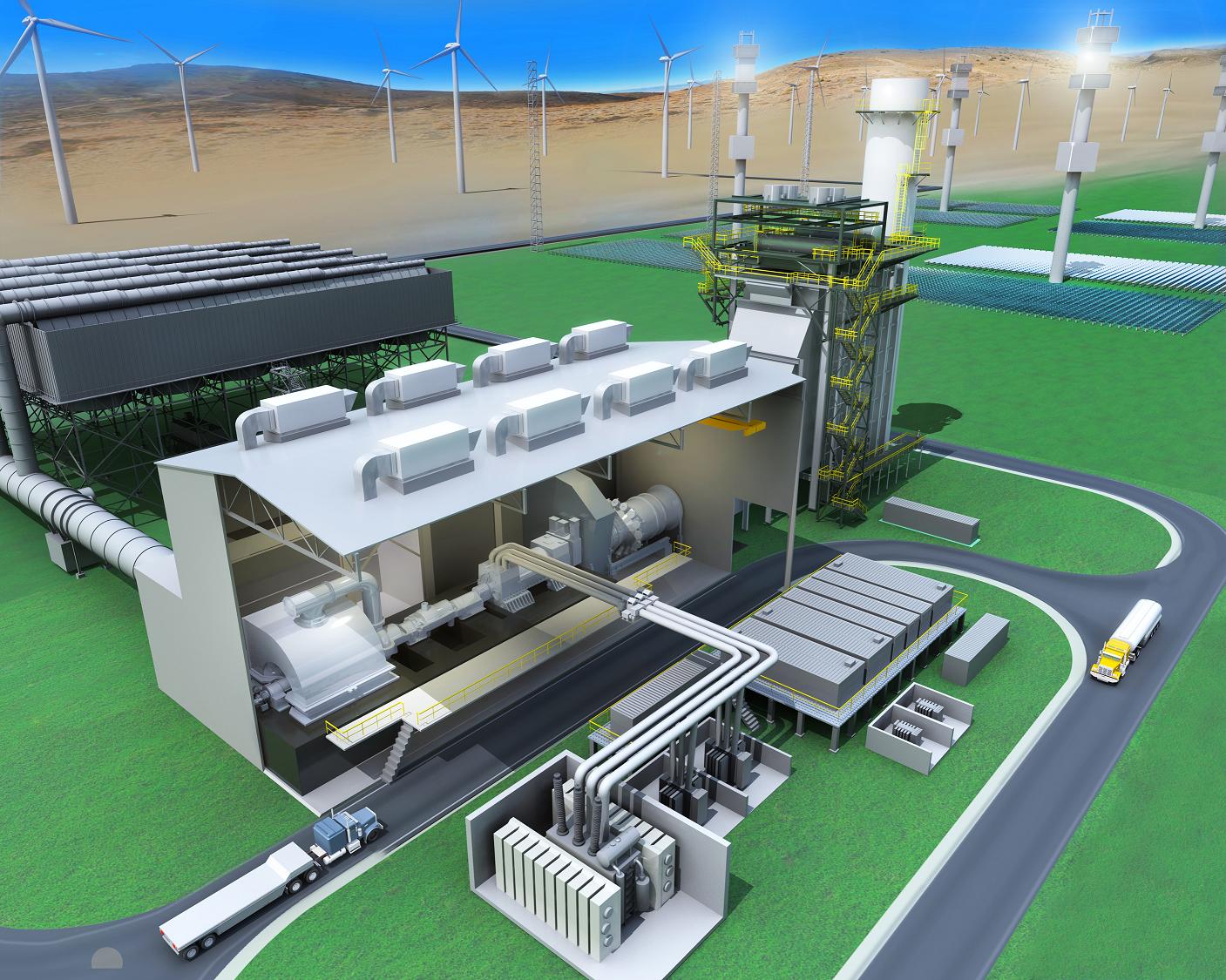

The term “combined cycle” refers to the use of two or more thermodynamic cycles in order to increase the overall efficiency of a power plant. In a combined cycle power plant, a gas turbine is used to generate electricity, while the waste heat from the gas turbine is used to power a steam turbine. This combination of technologies results in a power plant that is much more efficient than either a gas turbine or steam turbine alone.

Combined cycle power plants are able to achieve thermal efficiencies of around 60%, which is significantly higher than the approximately 35% thermal efficiency that can be achieved by either a gas turbine or steam turbine alone. The increased efficiency of combined cycle power plants means that they are able to generate more electricity while emitting less greenhouse gasses.

One benefit of combined cycle turbines is that they can use a variety of fuel sources, including natural gas, biogas, and even waste heat from other industrial processes. Combined cycle turbines are also relatively small and can be easily added to existing power plants or built as standalone units. Combined cycle turbines offer an efficient and versatile option for generating electricity.

Advantages of Combined Cycle Turbines

The advantages of combined cycle turbines are many and varied, but can be summarized as follows:

- Increased Efficiency: Combined cycle turbines are significantly more efficient than traditional single cycle turbines, meaning that more energy can be generated from a given amount of fuel. This leads to lower fuel costs and emissions.

- Greater Flexibility: Combined cycle turbines can be quickly and easily adapted to changing power demands, making them ideal for use in grid systems. This flexibility also makes them well suited for use in backup or peaking power plants.

- Improved Reliability: The increased efficiency of combined cycle turbines leads to improved reliability and availability, as there are fewer opportunities for component failure. This results in lower maintenance costs and increased uptime.

Types of Combined Cycle Turbines

There are two main types of combined cycle turbines:

- Gas turbine-based

- Steam turbine-based

The gas turbine-based system uses natural gas to power a generator that produces electricity. The exhaust from the gas turbine is then used to heat water, creating steam that powers a second turbine. This type of system is more efficient than a single cycle system because it uses the waste heat from the first turbine to power the second.

The steam turbine-based system is similar, but instead of using natural gas, it uses nuclear fission or fossil fuels like coal or oil. The steam produced powers a second turbine, again increasing efficiency.

Both types of combined cycle turbines have their benefits and drawbacks. Gas turbine-based systems are less expensive to build and maintain, but they produce more carbon dioxide emissions. Steam turbine-based systems are more expensive to build and require more maintenance, but they don’t produce as many emissions.

How to Find the Right Combination of Gas and Steam Turbines?

There are many factors to consider when choosing the right combination of gas and steam turbines for your power plant. The most important factor is efficiency. Combined cycle turbines are able to achieve higher levels of efficiency than either gas or steam turbines alone. Other important factors to consider include:

-The size of the power plant

-The type of fuel you are using

-The climate conditions where the power plant will be located

-The costs of construction and operation

When it comes to combined cycle turbines, bigger is not always better. The size of the power plant and the type of fuel you are using will both play a role in determining the optimum size for your turbine. Climate conditions can also impact the choice of turbine size. For example, if the power plant is located in a cold climate, a larger turbine may be needed to maintain efficiency.

Cost is always an important consideration when choosing any type of power plant equipment. Combined cycle turbines tend to be more expensive than either gas or steam turbines alone. However, they also have the potential to save money over time by reducing fuel costs and increasing efficiency.